A

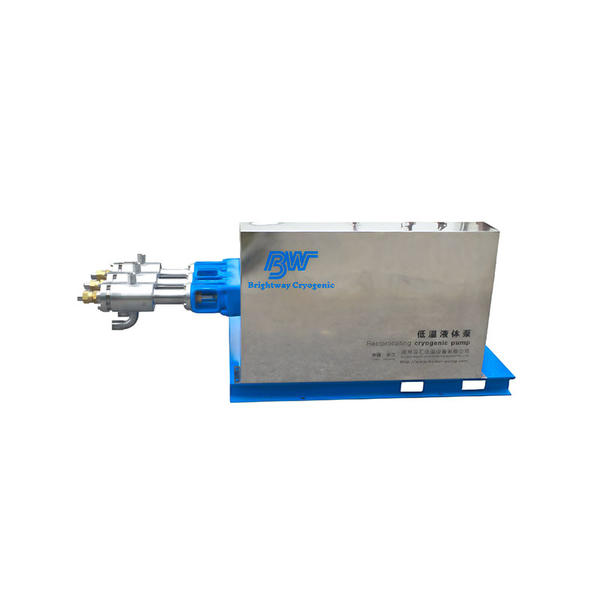

cryogenic liquid pump is a device used to transfer liquid cryogens, such as liquid nitrogen or liquid helium, from one vessel to another. Cryogens are substances that are cooled to extremely low temperatures, typically below -150°C, and are used in various industries for applications such as refrigeration, food processing, medical and scientific research, and manufacturing.

The cryogenic liquid pump works by compressing the liquid cryogen and raising its pressure to a level that allows it to be transferred to another vessel or process. The pump typically consists of a motor, a pump head, a pressure control system, and safety features such as pressure relief valves.

There are different types of cryogenic liquid pumps available, including positive displacement pumps and centrifugal pumps. Positive displacement pumps are used for low-flow applications and can handle both liquid and gas phases of cryogens. Centrifugal pumps, on the other hand, are used for high-flow applications and are typically used for transferring liquid cryogens only.

The function of the drive end of the pump is to change the rotating motion of the motor into a reciprocating motion and slow down the speed, and transfer the output power of the motor to the bottom of the cold end. The motor is converted and slowed down by the belt pulley, drive shaft, eccentric wheel, connecting rod and cross head components. The shaft, eccentric wheel and bearing structure of the transmission system are splash oil type, which makes the life of the power system greatly extended. The compression end of the cold end consists of a filter, a cylinder liner, a pump body, a piston assembly, a seal ring, a liquid inlet valve, a liquid discharge valve, etc.