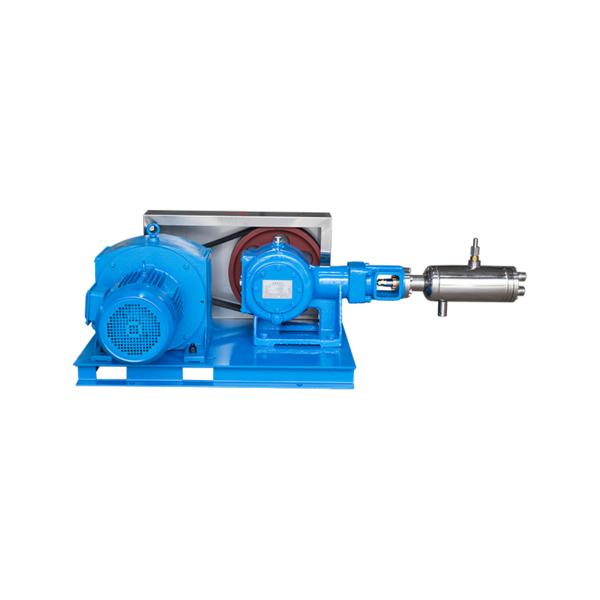

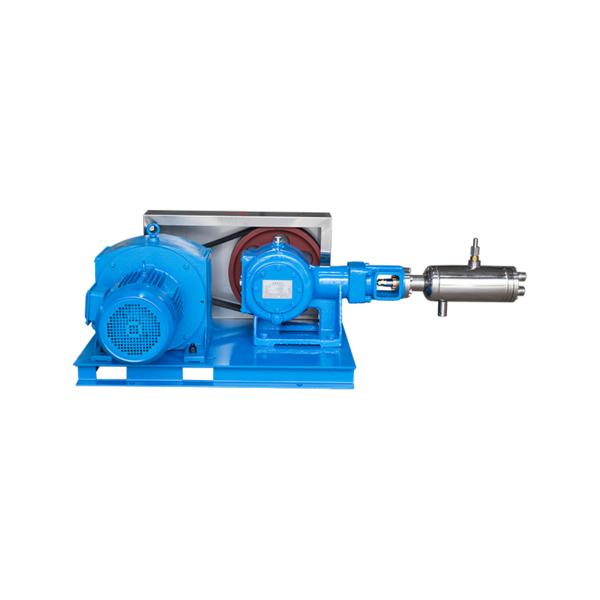

Using a

cylinder filling pump can have several environmental considerations that should be taken into account to minimize negative impacts on the environment. Here are some key factors to consider:

Emissions and Air Quality: Cylinder filling pumps may produce emissions during operation, especially if they are powered by fossil fuels. It is essential to ensure that the pump meets emission standards and is regularly maintained to reduce air pollution.

Noise Pollution: The operation of a cylinder filling pump can generate noise pollution, which may disturb nearby communities or wildlife. Noise reduction measures, such as sound barriers or operating during specific hours, can help mitigate this impact.

Energy Efficiency: Using energy-efficient pumps can reduce overall energy consumption and lower greenhouse gas emissions. Consider investing in modern, energy-efficient equipment to minimize the environmental footprint.

Spill Prevention: Accidental spills during the filling process can lead to the release of hazardous substances into the environment. Implementing proper spill prevention and containment measures is crucial to avoid soil and water contamination.

Waste Management: Proper handling and disposal of waste generated during the cylinder filling process are essential. This includes ensuring that hazardous materials are appropriately stored and disposed of in compliance with relevant regulations.

Water Conservation: If the cylinder filling pump uses water as a coolant or part of its operation, water conservation practices should be implemented to minimize the impact on local water resources.

Land Use and Site Selection: When installing a cylinder filling pump station, careful consideration should be given to its location to avoid sensitive ecological areas, habitats, or protected zones.

Regulatory Compliance: Ensure that all applicable environmental regulations and permits are obtained and adhered to when using a cylinder filling pump. This includes complying with emissions standards, waste disposal regulations, and other environmental requirements.

Material Selection: Opt for materials that are durable, non-toxic, and recyclable when constructing and maintaining the pump system to reduce the overall environmental impact.

Monitoring and Auditing: Regularly monitor the pump's operation and conduct environmental audits to identify and address any potential environmental issues promptly.

By considering these environmental considerations and implementing appropriate measures, the use of a cylinder filling pump can be made more environmentally friendly, helping to protect ecosystems and reduce the overall environmental impact of the operation.